In the world of electronics, ensuring the safety and functionality of devices is of paramount importance. One vital component that helps achieve this goal is conductive foam. This versatile material is specifically designed for electromagnetic interference (EMI) shielding, which protects sensitive electronic components from disruptive and potentially damaging electromagnetic emissions.

In the world of electronics, ensuring the safety and functionality of devices is of paramount importance. One vital component that helps achieve this goal is conductive foam. This versatile material is specifically designed for electromagnetic interference (EMI) shielding, which protects sensitive electronic components from disruptive and potentially damaging electromagnetic emissions.

The Science Behind Conductive Foam: How it Works for EMI Shielding

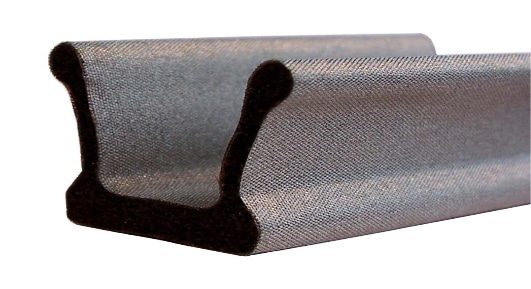

Conductive foam is a unique material made by infusing open-cell foam with conductive particles, such as carbon, nickel, or silver. These particles create a conductive network within the foam, enabling it to effectively absorb and dissipate electromagnetic radiation. When used for EMI shielding, conductive foam forms a barrier that prevents unwanted electromagnetic emissions from interfering with the operation of electronic devices.

Versatility and Adaptability: The Many Uses of Conductive Foam in EMI Shielding

Conductive foam’s versatility makes it ideal for many EMI shielding applications. Some common uses include:

- Electronic Enclosures:Conductive foam can be used as a gasket material in electronic enclosures, providing an EMI shield that prevents interference between internal components and external sources of electromagnetic radiation.

- Cable Shielding:Wrapping cables with conductive foam can help reduce EMI emissions from the cable, minimizing the risk of interference with other electronic devices.

- Component-Level Shielding:When specific electronic components are susceptible to EMI, conductive foam can be cut and shaped to fit around these components, providing targeted EMI shielding.

Conductive foam is an innovative material with remarkable properties, making it an ideal choice for EMI shielding applications. Its flexibility, lightweight nature, cost-effectiveness, and ease of use make it an essential tool for protecting electronic devices and components from potentially harmful electromagnetic emissions. By understanding the science and benefits of conductive foam, we can better appreciate its vital role in maintaining the safety and functionality of our electronic devices.